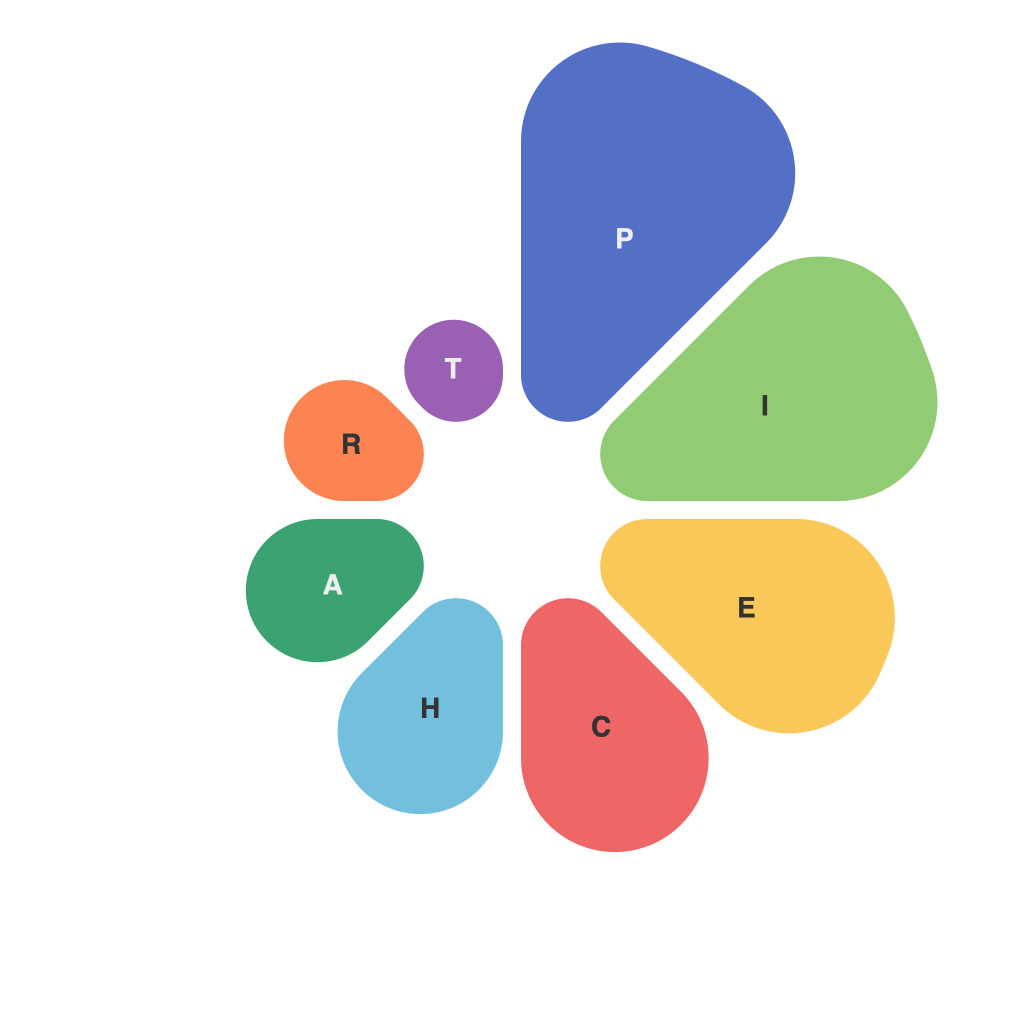

In an era marked by technological prowess and innovation, industries around the world are undergoing remarkable transformations. One industry that has found itself at the forefront of this dynamic change is plant engineering, with modern Rose Chart technology leading the charge. This article delves into the intricacies and prospects of the dynamic developments within this field, outlining how Rose Chart technology is not only revolutionizing the industry but also presenting unprecedented opportunities.

The concept of the Rose Chart, first used in the 18th century, has evolved beyond its traditional application as a navigational tool, to become a cornerstone of modern plant engineering. Its unique visual layout allows engineers and professionals to comprehend complex systems quickly and accurately, breaking down the complexities of process plants into easily digestible and interactive graphics.

**The evolution of Rose Chart technology**

The evolution of Rose Chart technology has been spurred on by the exponential growth of digital tools and software solutions. Unlike the simpler, more rudimentary charts of the past, modern Rose Charts are fully integrated with state-of-the-art systems that enable rapid data analysis, visualization, and planning. These advanced versions offer a suite of functionalities that streamline the engineering process at every turn.

At the heart of this advancement is the utilization of 3D modeling. Engineers can now create hyper-realistic models of plants, equipment, and interconnections to gain a comprehensive understanding of the entire manufacturing process. This level of detail is previously unattainable, allowing for precise maintenance, optimization, and troubleshooting.

**Transformative Benefits in Plant Engineering**

The integration of Rose Chart technology has ushered in a plethora of benefits for the plant engineering landscape:

1. **Enhanced visualization and communication**: Rose Charts facilitate clear communication between stakeholders, from designers to operators. The graphical representations simplify the sharing of complex information, ensuring that everyone is on the same page.

2. **Improved safety**: By making the process clear and intuitive, Rose Charts help reduce the risk of accidents. Employees can quickly identify critical systems and understand the interplay of various components, creating a safer working environment.

3. **Increased efficiency**: The detailed insights from Rose Chart analysis allow engineers to identify bottlenecks and inefficiencies, optimizing plant performance and operational processes.

4. **Streamlined maintenance**: Predictive maintenance is made possible with Rose Charts, allowing engineers to proactively address potential issues before they arise.

5. **Cost savings**: Improved efficiency and safety directly translate into significant cost savings, both in terms of operational and maintenance expenses.

**Challenges and Opportunities**

Despite its transformative potential, Rose Chart technology is not without its challenges. Implementation requires substantial investment in software, training programs, and hardware, alongside a cultural shift towards adopting new digital solutions.

However, the opportunities for growth and innovation are immeasurable:

1. **Smart integration**: Combining Rose Chart technology with the Internet of Things (IoT) can yield a network of connected plants that can continuously gather and analyze data for optimization.

2. **Customization and scalability**: As industries evolve and new challenges present themselves, the ability to develop Rose Charts tailored to specific needs becomes an invaluable asset for engineering teams.

3. **Global reach**: The digital nature of Rose Chart technology makes it accessible to remote teams and international collaboration, opening up new possibilities for cross-continent engineering projects.

In conclusion, the advent of modern Rose Chart technology has injected new life into plant engineering, fundamentally altering how industries approach design, maintenance, and optimization. As this technology continues to advance, plant engineers are positioned to take advantage of a treasure trove of opportunities that will shape the future of manufacturing processes. The potential is vast, and the future is bright for plant engineering in the context of these dynamic developments.